In job shop settings and during bespoke manufacturing processes, the need for high standards is extremely intense. Staying competitive as a job shop could mean a range of things including, minimising programming, setup, and processing times.

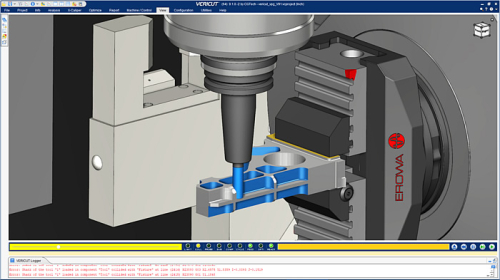

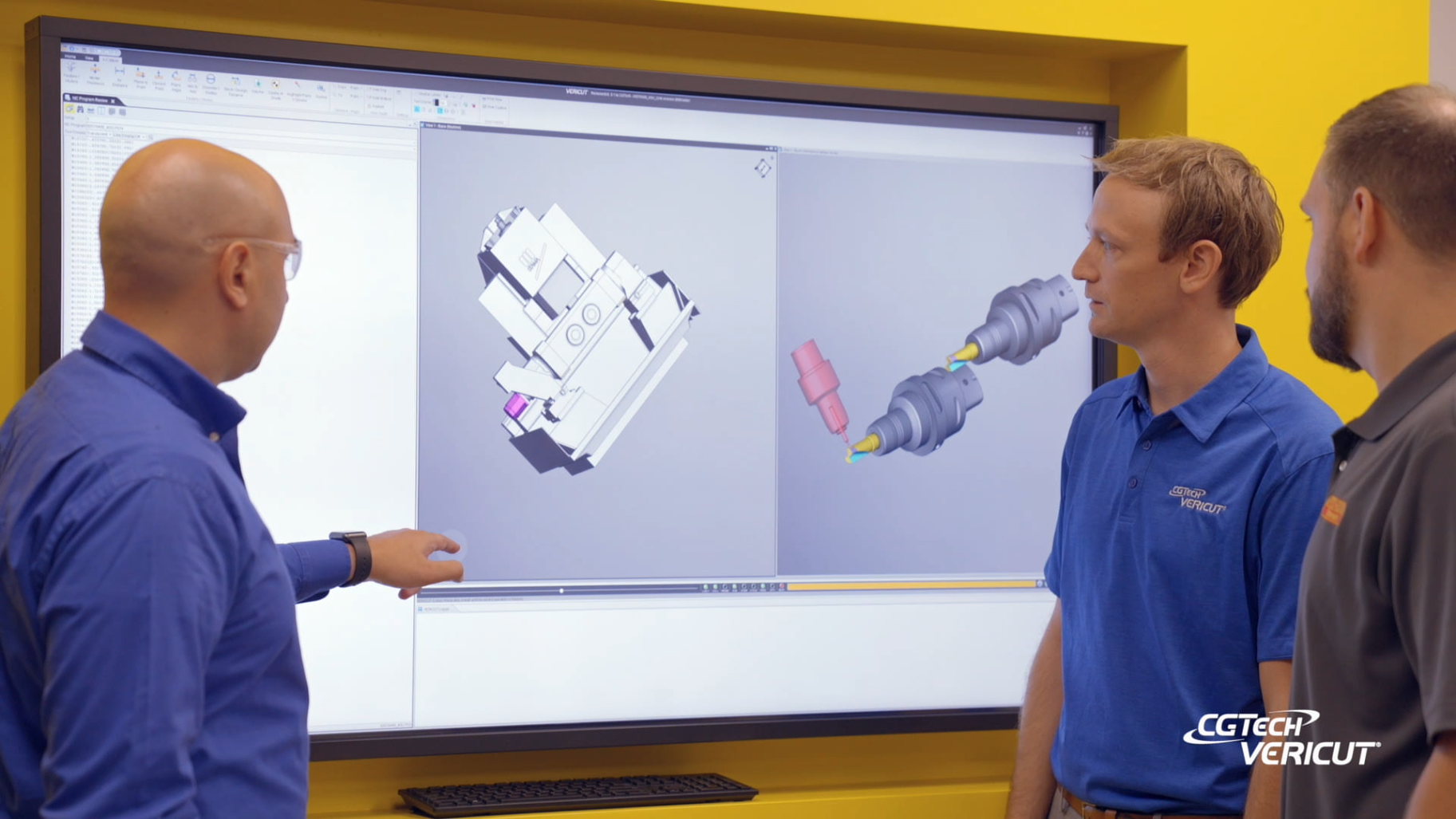

You can use simulation in your job shop processes to improve efficiency. Integrating CGTech's VERICUT software makes the production of high-quality components easier and more efficient than ever.

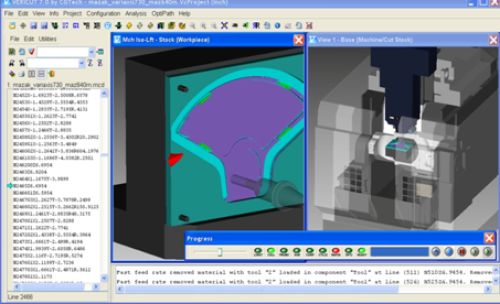

Simulating machine integration and manufacturing processes in job shops can help to cut machining times and eliminate prove outs. The VERICUT system will help you to identify collisions, gouges, and other issues to help prevent real-life incidents.

Adding simulation software to your processes also helps you to make sure your job shop has the right tools for the job. In reducing the risk of errors and improving confidence in your new job shop processes, VERICUT is a good indicator of where to invest in your processes.

In small manufacturing systems which handle custom processes, job shops need to be as efficient as possible to hit manufacturing requests quickly and cost-effectively.

Reducing set-up time by simulating different configurations of machine integration helps you bring quicker quality to your clients.

Explore Resources and User Stories

-

Blackmore Precision Engineering User Story

With an impressive machine shop that equals many of the motorsport teams that it supplies, Blackmore Precision Engineering has invested in some of the very latest advanced manufacturing equipment to produce complex tight tolerance components of outstanding quality within demanding timescales. Helping the company achieve its promised delivery is VERICUT CNC simulation and optimisation software.

-

Castle Precision Engineering User Story

"When manufacturing high-value components for such critical applications, we need to have confidence that we’re using the very best tools for the job, and VERICUT delivers." - Castle Precision Engineering

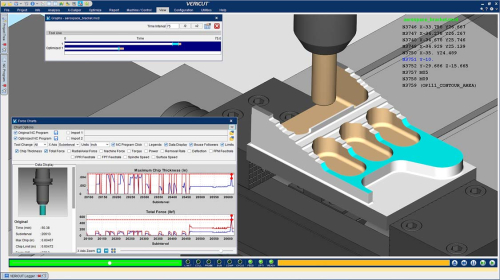

Glasgow-based Castle Precision Engineering has been an advocate for the use of VERICUT CNC simulation software on its shopfloor for many years, protecting high value customer components as well as its own advanced machine tools. More recently the company has embraced the efficiency and productivity gains offered by the FORCE module of the software.

Learn more about how Castle Precision Engineering uses VERICUT Force to improve productivity and gain efficiencies.

-

Advanced Manufacturing (AML) User Story

VERICUT from CGTech is a key component of business success at this rapidly expanding precision machining company, which serves a plethora of customers in sectors such as aerospace, energy and defence. More recently, AML has embraced the efficiency and productivity gains offered by VERICUT’s Force™ module, which is driving tool life gains. Read about how VERICUT's Force Optimization module has helped them achieve a 30-40% reduction in machine cycle times.

-

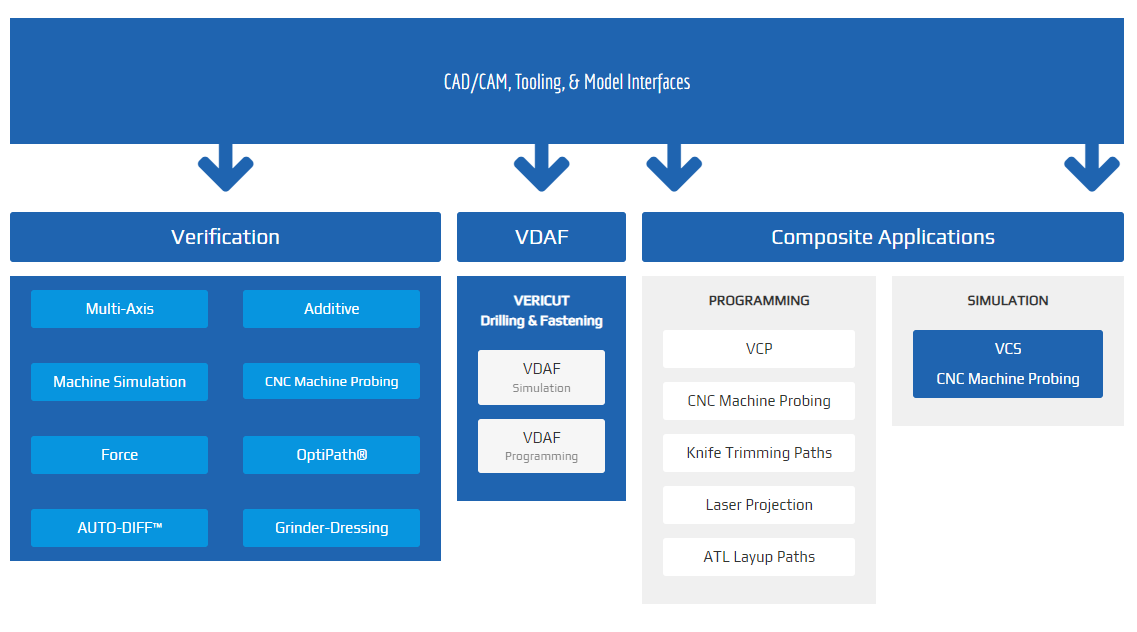

Explore Our Full Product Line

VERICUT offers solutions in machine simulation, verification, optimization, and more. Find the right modules to protect your CNC machines while increasing throughput.

-

VERICUT Force Optimization

VERICUT Force Optimization optimizes new and existing NC programs according to changes in cutting conditions. Protect your CNC machines and extend your tool life; watch the user story from Sandvik Coromant Mebane.

Germany

Germany Italy

Italy USA

USA South Korea

South Korea UK

UK India

India France

France China

China Japan

Japan