The Hidden Cost of Tool Breakage

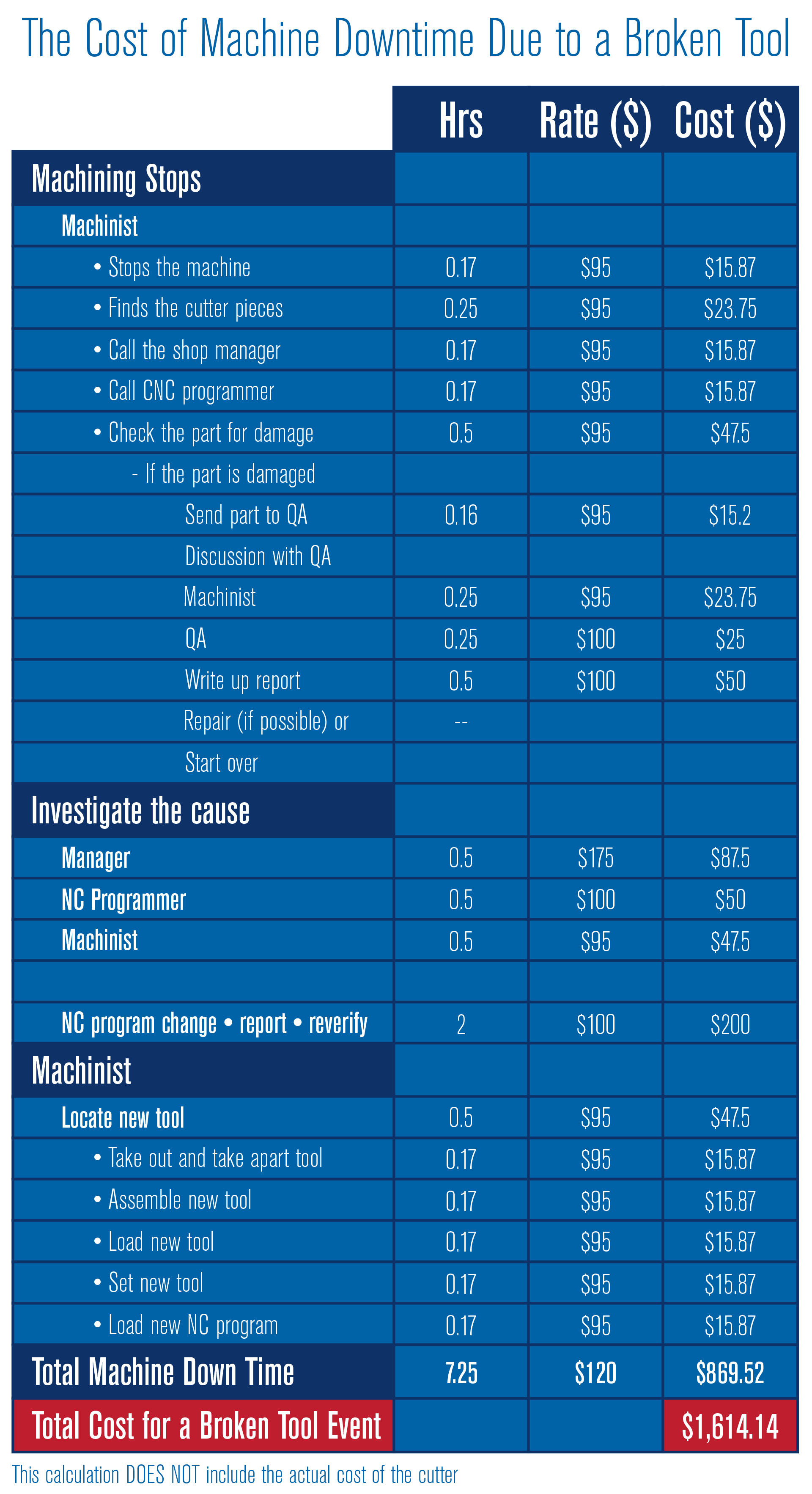

The true cost of breaking a tool includes much more than just the cost of the tool itself. Machine downtime, and the cost of time associated with investigating and replacing the tool must also be considered.

Why Do CNC Machines Break?

Tool breakage is a major problem for machining operations. There are many reasons why CNC Machines break including.

Mechanical Failures (broken tools)

CNC Machines are complex instruments consisting of numerous mechanical components. These components can wear out or become damaged due to lack of maintenance, inadequate lubrication, overuse and high loads.

Software and Programming Errors

Programming errors, such as incorrect tool paths, incorrect feed rates, or software bugs, can cause the machine to operate incorrectly or unexpectedly. These errors can result in collisions, tool breakage, or other mechanical failures. Eliminating NC programming errors is essential to smooth operation.

Maintenance

Neglecting routine inspections, lubrication, cleaning, and calibration can result in the accumulation of debris, increased friction, misalignment, or degraded performance. These issues can eventually lead to machine breakdowns.

Wear and Tear

CNC machines are often in continual operation which can result in wear and tear of various components such as cutting tools, guide rails and bearings. If these components are not regularly inspected, maintained, or replaced, when necessary, they can fail and cause machine breakdowns.

What are the costs of CNC Machine Breakage?

The true cost of CNC Machine Failure is higher than many people think. There are several costs which can add up to cost your business time and money.

1. Downtime: Downtime is the primary problem with CNC machine breakage. The machine will be out of operation until the issue is identified, diagnosed, and repaired. This can result in a loss of productivity and delays in the production process.

2. Production Delays: If the CNC machine is a critical part of the production line or process, its breakdown can lead to production delays. This can impact the overall workflow and scheduling, potentially causing a ripple effect on downstream operations, customer orders, and delivery timelines.

3. Increased Costs: CNC machines are expensive assets, and any breakdown will likely result in additional costs for your company. Repairing or replacing faulty components, hiring technicians, and obtaining replacement parts can all contribute to increased expenses. Revenue can be lost if the machine remains idle.

4. Quality: A malfunctioning CNC machine may produce parts or products that do not meet the required specifications or standards. This can lead to flawed items, rework requirements, or even scrap production, all of which can incur additional costs and impact customer satisfaction.

5. Maintenance and Repair: CNC machines require regular maintenance to ensure optimal performance and prevent breakdowns. When a machine breaks down, it highlights the importance of maintenance practices. As a result, additional efforts might be required to improve preventive maintenance procedures, schedule regular inspections, and implement effective troubleshooting protocols.

6. Customer Satisfaction: If CNC machine breakdowns cause delays in filling customer orders or compromise the quality of products, it can eat away at customer trust. Unhappy customers may seek alternative suppliers, affecting long-term business relationships and revenue.

How Does VERICUT Help Stop Machining Breakdowns?

VERICUT CNC simulation software helps to detect errors, collisions and areas of inaccuracy. It has several benefits including

- Avoid machine collisions, safely retract complex clamping situations

- Reduce start up times

- Increase tool life

- Optimised, faster NC Programs

- Improve part quality

- Reduce processing times

- Increase machine capacity

- Savings when setting up new parts

- Avoid rejects

- Protection of expensive production equipment

- Reduction of manufacturing costs & optimization of processes!

- VERICUT saves time and money

Maximize productivity and cutting tool performance with VERICUT Force. Use our interactive savings calculators to see how much you can save.

Want to learn more about Force? Click here for more information, FAQ, user stories and more.

Germany

Germany Italy

Italy USA

USA South Korea

South Korea UK

UK India

India France

France China

China Japan

Japan