Force

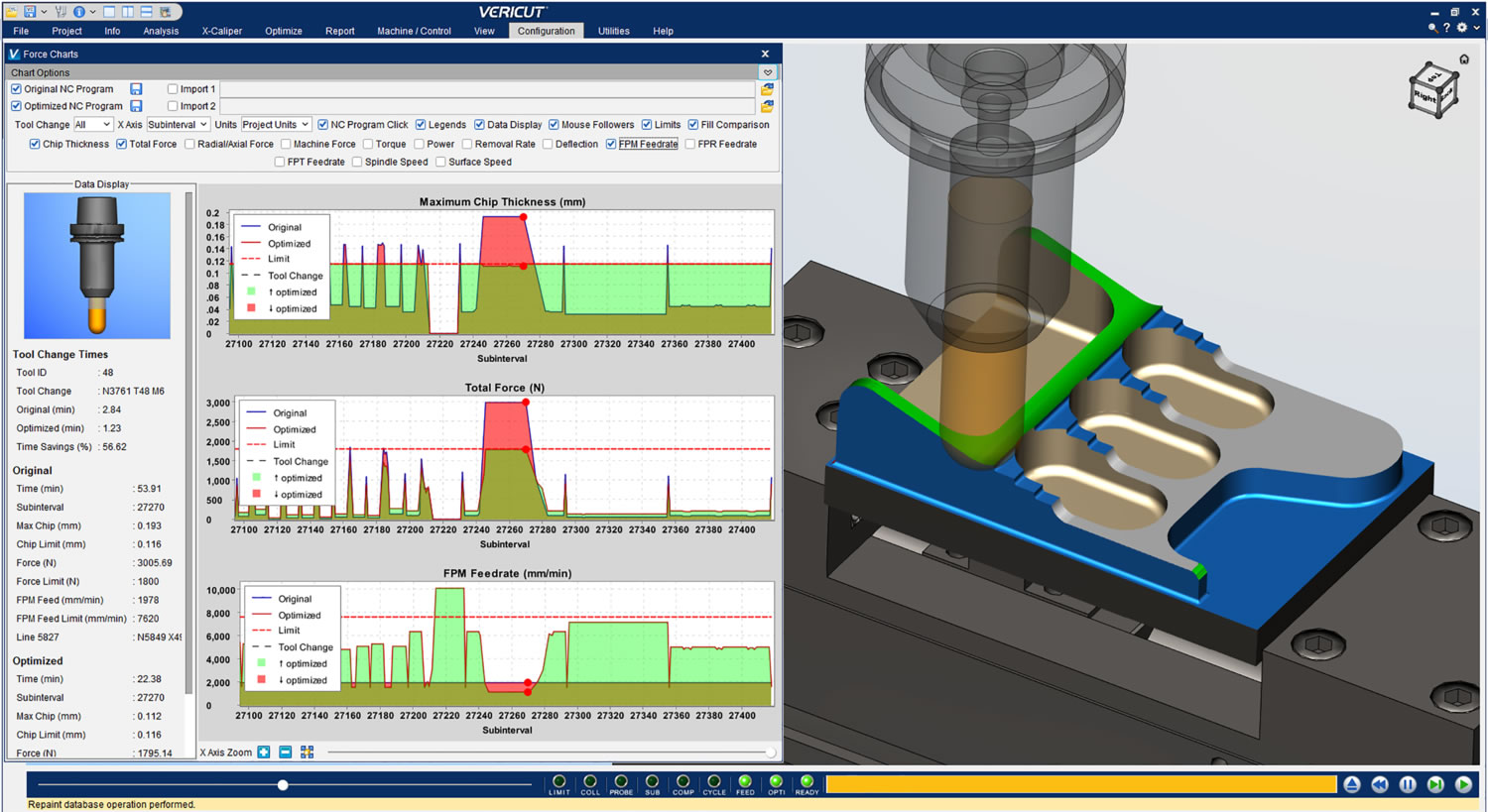

Reduce Machining times by 25% or more with VERICUT Force

Force is a physics-based optimization method that sets the maximum reliable feed for a particular cutting condition based on 4 factors:

Load on the cutting edge, spindle power, maximum chip thickness and maximum allowable feed. Force calculates ideal feed rates by analysing: tool geometry and parameters, material characteristics and cutting material, detailed cutting edge geometry and VERICUT Smart Part Technology. Force calculates cutting conditions using specific material characteristics, taking into account the strength of the material and the effects of friction and temperature. The material characteristics are based on actual cutting trials and not just on the basis of hypothetical calculations. Turning and drilling optimization functions will follow soon!

Force is ideal for difficult-to-machine materials and complex multi-axis operations such as 5-axis flank milling. Once the material has been defined, it can be applied to a wide range of cutting tools and machines in future NC machining operations. It is easy to set up and can also predict tool wear.

Contact us for a demonstration

22% savings right from the start

Premium AEROTEC benefited from the start with the new solution. The savings calculated so far are approximately 22 percent for the machine running times of the programs optimized with FORCE and also a significant improvement in tool life.

Optimize

VERICUT Force makes optimizing an NC program fast and easy. Force calculates the contact between the tool and material, cut-by-cut. Force also takes the cutting tool edge and the material into account to adjust the feedrates to be optimal and constant.

The first users of this technology have already achieved productivity gains of up to 50 percent.

Further advantages include:

- Significant cycle time savings

- Charted cutting condition information for NC program analysis

- FAST analysis and iteration for testing various cutting scenarios

- Maximized and more consistent chip thickness throughout the machining process

- Cut-by-cut analysis of the interaction between the cutting tool edge and the material

- Improved cutting tool performance—utilize cutting tool technologies to their full potential

- Prevention of undesirable cutting conditions like excessive force, HP/Torque, and tool deflection

Contact us for a demonstration

We also now have ...

- Force-Milling: Optimize milling processes for faster cycle times, maximized chip thickness and improved cutting tool performance.

- Force-Turning: Optimize lathe turning and mill-turn operations, when combined with Force Milling, for more efficient cutting conditions.

- Force Materials: Choose from our comprehensive catalogue of material characterization files to ensure ideal optimization matches your workpiece.

- Force Material Catalogue: Subscribe to our catalogue of material characterization and access all of available material characterization files.

- Force-Calibration: Calibrate materials for use with Force Optimization (Milling or Turning) via a material characterization file.

Germany

Germany Italy

Italy USA

USA South Korea

South Korea UK

UK India

India France

France China

China Japan

Japan