Our Industries

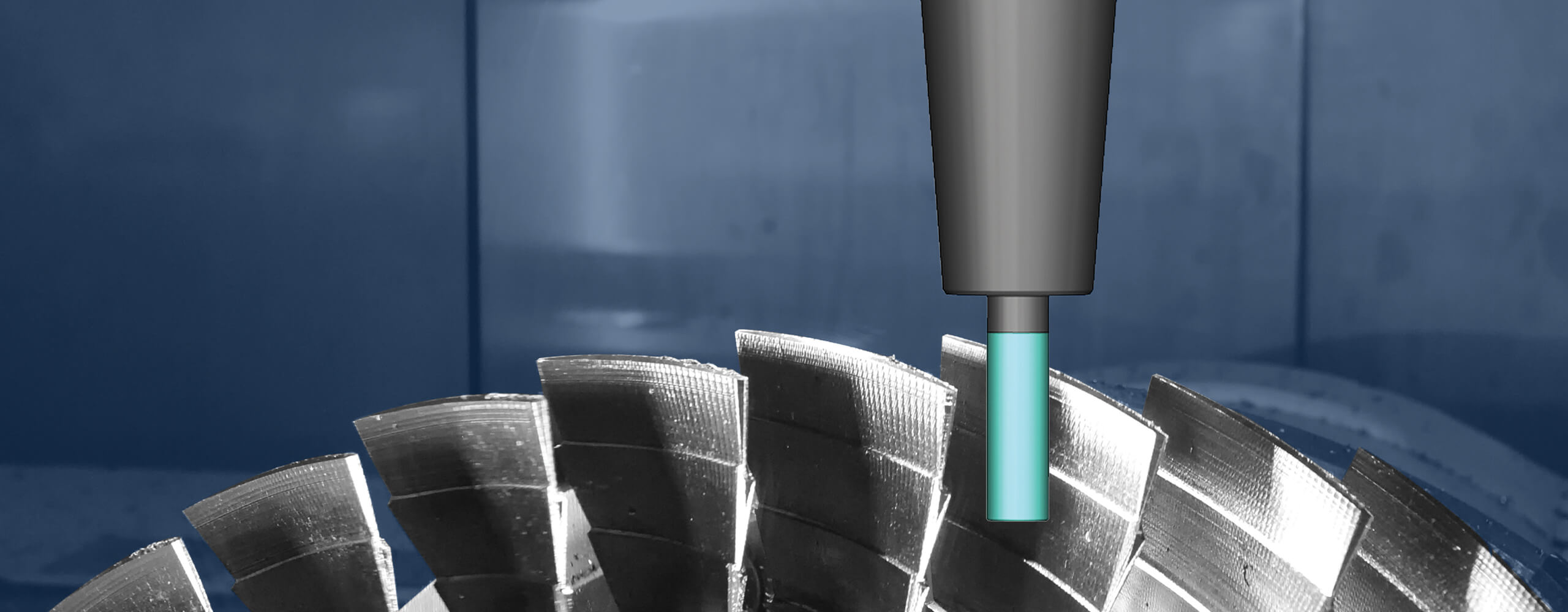

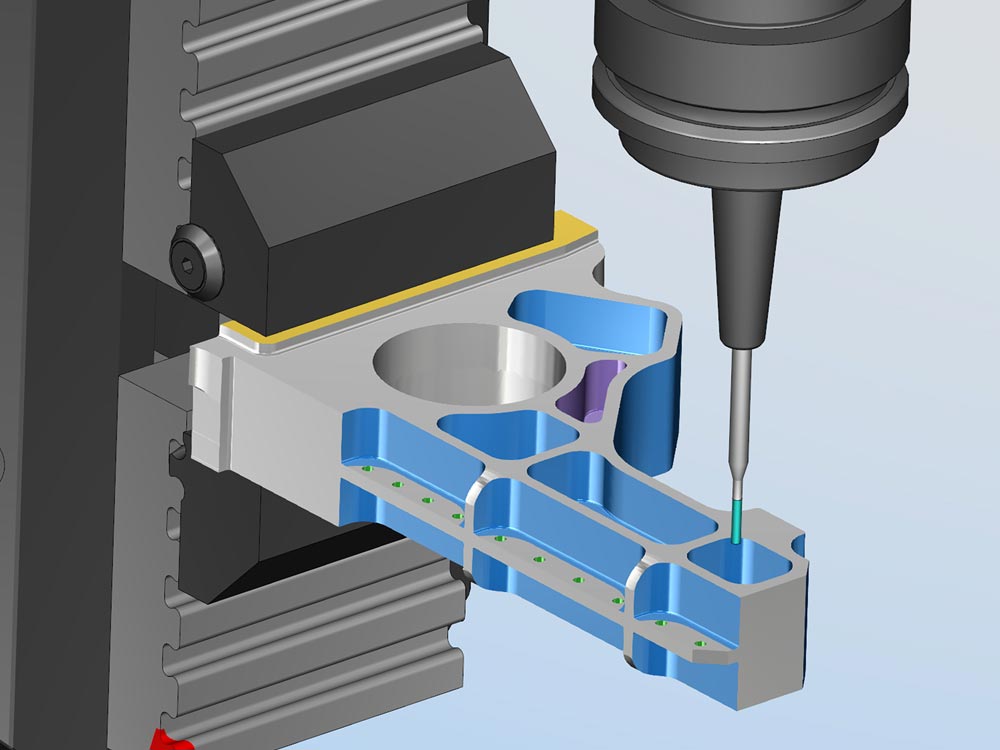

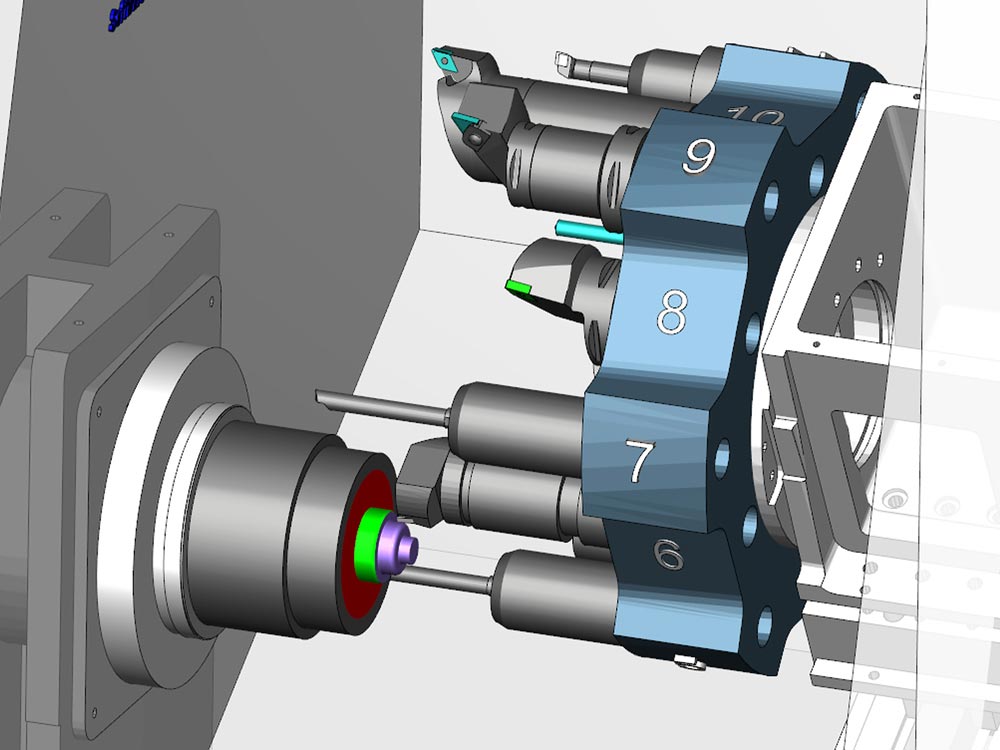

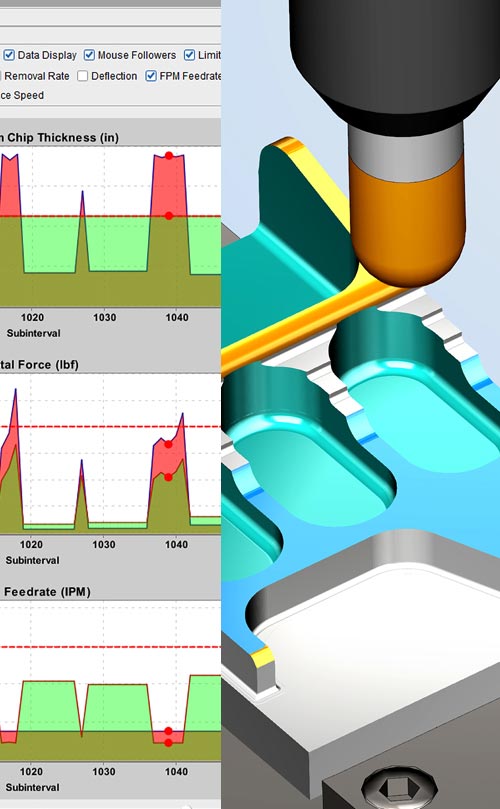

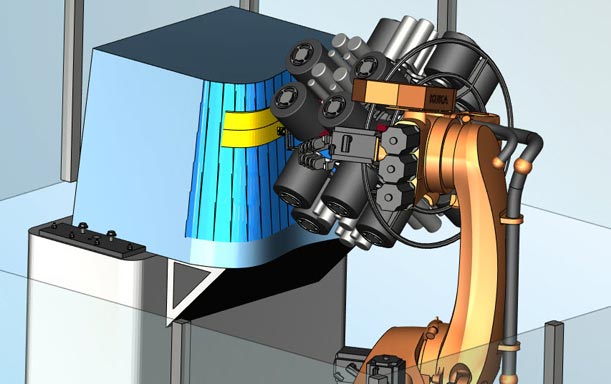

VERICUT is the standard for CNC machine simulation for traditional milling and turning machines, additive hybrid machines, and composites. Companies, universities, trade schools, and government agencies of all sizes use VERICUT.

Learn more how VERICUT saves time, money, and machines — all while producing higher quality parts for each industry we work in.

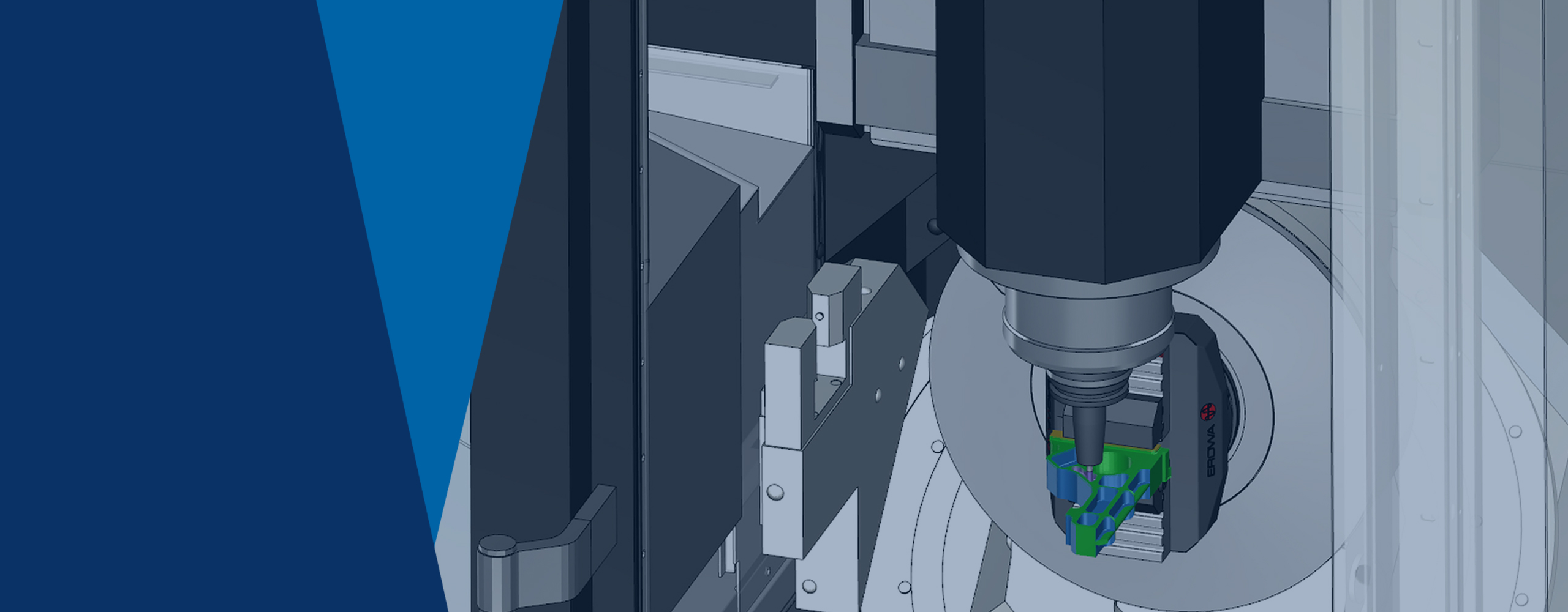

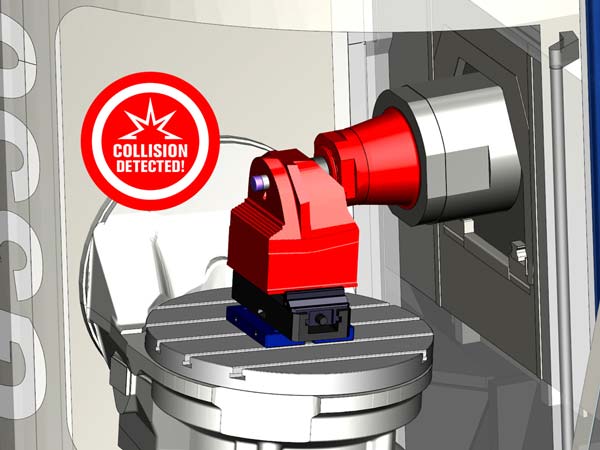

CGTech VERICUT – the world’s leading CNC simulation,

verification and optimisation software since 1988

Since 1988, CGTech has been the global leader in NC code simulation with VERICUT. We offer a wide range of products and solutions to make your CNC machines collision-free and your manufacturing processes more efficient. Working closely with our customers and partners around the world to understand their exact needs, we deliver superior technical and economical solutions through the use of advanced technologies.

Germany

Germany Italy

Italy USA

USA South Korea

South Korea UK

UK India

India France

France China

China Japan

Japan